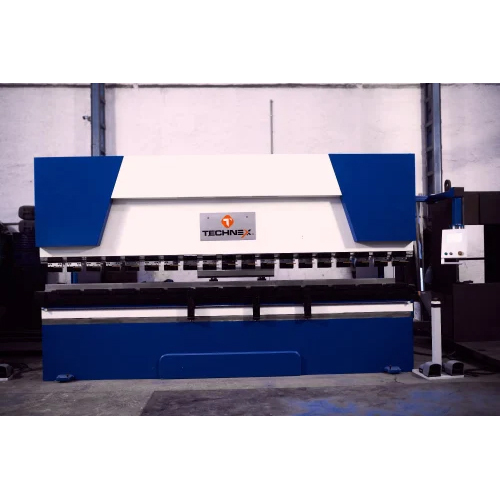

150 Ton Hydraulic Plate Bending Machine

500000 INR/Unit

Product Details:

- Automation Automatic

- Phase Three Phase

- Output Precision Sheet Bending

- Voltage 220 Volt (v)

- Dimension (L*W*H) 4000 x 1700 x 2400 mm

- Product Type Plate Bending Machine

- Bending Angle 0-180 Degrees

- Click to View more

X

150 Ton Hydraulic Plate Bending Machine Price And Quantity

- 500000 INR/Unit

- 1 Unit

- Heavy Duty Welded Steel

- Up to 600 mm (motorized)

- Emergency Stop and Foot Switch

- PLC Based Control Panel

- Up to 250 Bar

- 300 Liters

- Manual and Auto

150 Ton Hydraulic Plate Bending Machine Product Specifications

- Plate Bending Machine

- 8 mm/sec

- 0-180 Degrees

- 150 Ton

- 1440 RPM

- India

- Minimum 2 Times Material Thickness

- Up to 12 mm (MS) / 8 mm (SS) thickness

- Mild Steel, Stainless Steel

- Sheet Bending

- Hydraulic Plate Bending Machine

- 7.5 kW

- Continuous, up to 30 operations/min

- Automatic

- Three Phase

- Blue and White

- Precision Sheet Bending

- 220 Volt (v)

- 4000 x 1700 x 2400 mm

- Approx. 7000 kg

- Heavy Duty Welded Steel

- Up to 600 mm (motorized)

- Emergency Stop and Foot Switch

- PLC Based Control Panel

- Up to 250 Bar

- 300 Liters

- Manual and Auto

150 Ton Hydraulic Plate Bending Machine Trade Information

- 7 Days

- All India

Product Description

TECHNEX brand. We are sheet metal machinery manufacturers & exporters. We make , NC Hydraulic Press Brake Machines, Hydraulic Shearing Machines, Power Press Machines, Hydraulic Press Machines etc.. our manufacturing plant is located in Rajkot Guj. India

Specification

| Country of Origin | Made in India |

| Control Type | CNC |

| Cutting Load | >150 ton |

| Max Sheet Width | 4 meter |

| Brand | Technex |

| Usage/Application | Sheet Bending |

Advanced Bending Technology

This hydraulic plate bending machine features a powerful PLC-based control panel for precise and repeatable operations. Its robust frame and advanced hydraulic system provide exceptional stability, allowing for reliable performance even in demanding manufacturing environments. With automated capabilities and flexible stroke adjustments, you can achieve optimal results for a variety of sheet bending tasks.

Enhanced Safety and Efficiency

Designed with operator safety in mind, this machine includes emergency stop and foot switch controls. The motorized back gauge allows quick, accurate positioning, speeding up workflow and minimizing manual intervention. Combined with continuous production capability and low maintenance requirements, it offers a highly efficient solution for metalworking.

Versatile Industrial Applications

With its heavy-duty construction and ability to bend both mild steel and stainless steel, this machine is perfect for diverse sectors such as fabrication, automotive, and construction. Its high bending strength, adjustable angle, and customizable back gauge range ensure adaptability across various industrial sheet bending applications.

FAQs of 150 Ton Hydraulic Plate Bending Machine:

Q: How does the PLC-based control panel improve the bending process?

A: The PLC-based control panel enables precise automation, allowing you to set and monitor bending parameters accurately. This results in consistent output, minimizes human error, and streamlines operation changeovers for enhanced productivity.Q: What materials can this hydraulic bending machine process, and in what thicknesses?

A: This machine can bend mild steel plates up to 12 mm thick and stainless steel plates up to 8 mm thick, providing versatility for a range of industrial applications.Q: When should the stroke adjustment be used, and how is it operated?

A: Stroke adjustment is necessary when different sheet thicknesses or bending angles are required. The machine supports both manual and automatic stroke adjustments, providing flexibility based on your production needs.Q: Where is this plate bending machine manufactured and exported from?

A: The machine is manufactured in India and is available through distributors, exporters, manufacturers, suppliers, and traders in the region, ensuring wide accessibility for both domestic and international customers.Q: What is the process for bending sheets with this machine?

A: To bend sheets, load the material securely, use the PLC panel to input desired parameters, adjust the back gauge and stroke if needed, and operate the machine using the foot switch. The entire process is safeguarded by emergency stop features for operator safety.Q: How can this machine benefit industrial sheet metal operations?

A: With its automation, high bending strength, and continuous production capability (up to 30 operations per minute), this machine boosts efficiency, ensures precise bends, and reduces cycle time, making it highly valuable for large-scale manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese